Uyini umgomo wokusebenza komshini weqhwa? Kulinganiselwa ukuthi wonke umuntu akayazi le nkinga. Lesi sihloko sizochaza umgomo wokusebenza kanye nokuhamba komsebenzi komshini weqhwa ngokuningiliziwe ngomdwebo wohlelo.

I-ice maker uhlobo lwemishini yesiqandisi epholisa amanzi ngesiqandisi sesistimu yesiqandisi ukuze kukhiqizwe iqhwa. Njengoba kuboniswe kuMfanekiso 1, isetshenziswa kakhulu emikhiqizweni yasemanzini, ukudla, imikhiqizo yobisi, imithi, ikhemistri, ukulondolozwa kwemifino nezinye izimboni. Ngokuthuthuka komphakathi kanye nokwenza ngcono okuqhubekayo kwezinga lokukhiqiza labantu, imboni yeqhwa iya ngokuya iba banzi futhi iba banzi, kanti nesidingo senhlalo semishini yeqhwa siyakhula.

Ⅰ. Isingeniso esifushane somgomo wokusebenza

Umgomo wesiqandisi somenzi weqhwa uboniswa esithombeni esilandelayo. Isiqandisi sicindezelwa yi-compressor sibe yigesi yokushisa ephezulu kanye ne-high-pressure, ipholiswe yi-condenser, ifakwe uketshezi olusezingeni lokushisa eliphakathi nendawo kanye noketshezi olunomfutho ophezulu, iphonswe uhlelo oludonsa kanzima, bese igeleza iye ku-evaporator futhi ihwamuke epayipini layo. Isiqandisi simunca ukushisa kwendawo ezungezile ukuze sibe yiqhwa amanzi, bese sigeleza sibuyela ku-compressor ngepayipi elibuyayo, bese siyacindezelwa futhi sikhishwe. Lo mjikelezo wenza amanzi abe yiqhwa kuze kube yilapho ama-ice cubes efinyelela ugqinsi oluthile.

Isiqandisi sicindezelwe sibe yi-high-temperature ne-high-pressure gas ku-compressor futhi sikhishwe, bese singena ngqo ku-evaporator ngepayipi lokuhambisa ukushisa, ukuze izinga lokushisa le-evaporator likhuphuke, bese ama-ice cubes ewa evaporator ngaphansi kwesenzo esihlangene sesiqandisi kanye namanzi angeziwe. Ngemva kokuqeda inqubo yokwenza iqhwa kanye, qhubeka uphinda kuze kube yilapho ama-ice cubes esiqandisini enqwabelana ngokuphelele, futhi inqubo yokwenza iqhwa imisiwe. Ngemva kokukhipha ama-ice cubes, umenzi weqhwa uqhubeka nomjikelezo ongenhla.

1. Inqubo yokwenza iqhwa

Ngemuva kokuthi umshini uvuliwe, faka inkinobho yokusebenza esimweni "Sokwenza Iqhwa 20". Ngalesi sikhathi, ukukhanya kwenkomba kuvuliwe, futhi iphampu yamanzi kanye ne-drainage solenoid valve ivuliwe imizuzwana embalwa (isikhathi esithile singasethwa) ukukhipha amanzi asele ethangini lamanzi, ngaleyo ndlela uqinisekise ukuthi amanzi asetshenziselwa ukwenza iqhwa masha futhi ahlanzekile. Ngesikhathi sokukhipha amandla, i-valve yokulawula ibuye ihlanzekile. ibona ukuthi amakhyubhu eqhwa esiqandisini agcwele yini Uma iqhwa lingagcwali, qala i-compressor, qalisa ifeni yokupholisa ye-condenser ngesikhathi esifanayo, vala iphampu yamanzi kanye ne-valve yokukhipha amanzi, bese uvula i-valve ye-solenoid yokungena emanzini ukuze ungene esimweni sokwenza iqhwa.

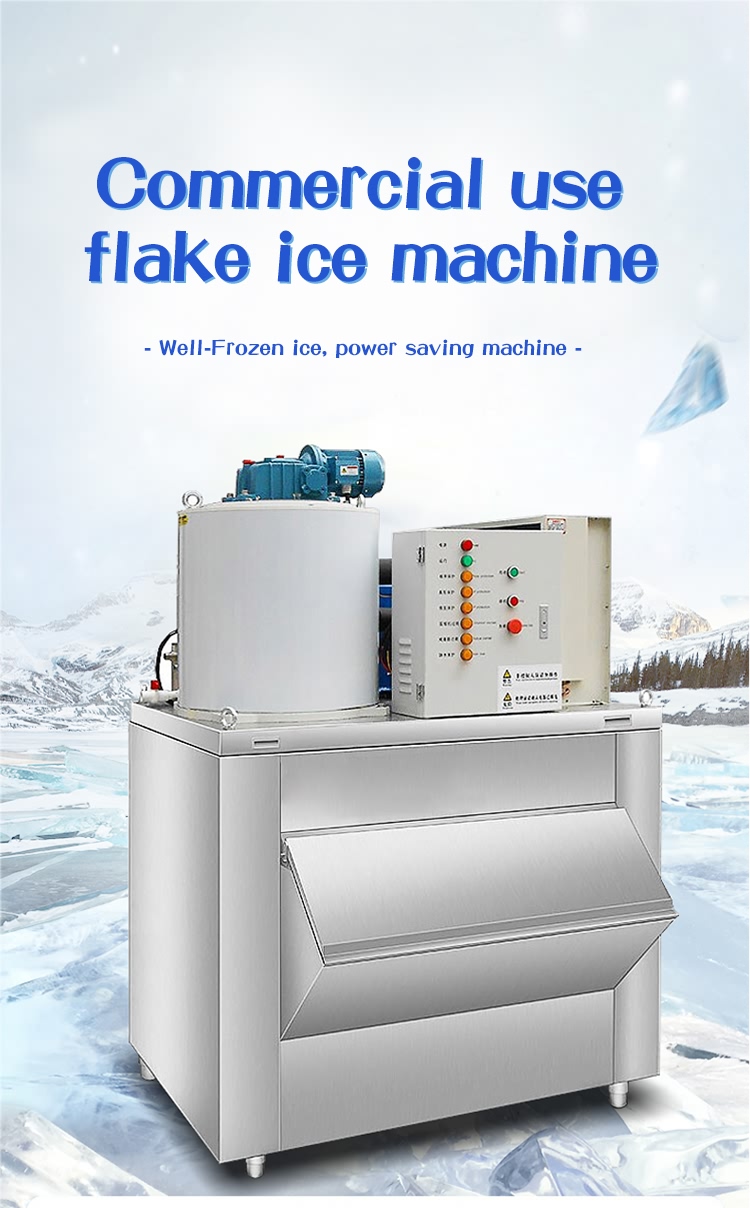

0.3T umshini weqhwa we-flake

Phakathi nayo yonke inqubo yokwenza i-ice kanye ne-deicing, i-compressor ihlale isebenza, i-valve yegesi eshisayo ivaliwe ngemva kokuba i-compressor iqalwe imizuzwana embalwa, iphampu yamanzi iqalwa ngemva kokuba i-compressor ipholise igumbi leqhwa (evaporator) imizuzwana embalwa, futhi i-valve yokungena kwamanzi ivaliwe lapho umtshina wezinga lamanzi uthintana namanzi ku-sink imizuzwana embalwa izinga lamanzi (uma i-detector ithinta izinga lamanzi). khanyisa), noma ngemva kwemizuzu embalwa yamanzi eqhubekayo. Ngaphansi kwesenzo sephampu yamanzi nesihlukanisi samanzi, amanzi ageleza ngokulinganayo engxenyeni ngayinye yegumbi eliqandayo. Ngokwakhiwa kwama-cubes eqhwa, izinga lamanzi liyehla futhi inkomba yezinga lamanzi iyaphuma. Ngalesi sikhathi, amanzi azogcwaliswa kanye kuze kube yilapho umtshina wezinga lamanzi uhlangana namanzi imizuzwana embalwa, ukuze kuqinisekiswe ukuthi kunamanzi anele okwenza iqhwa.

Enqubweni yokwenza iqhwa, ibhodi lokulawula le-elekthronikhi lizobona ngokuqhubekayo izinga lokushisa le-condenser, futhi uma izinga lokushisa layo lidlula izinga lokushisa elibekiwe, lizoqala isiphephetha-moya sokupholisa se-condenser ukuze sinciphise ngokushesha izinga lokushisa.

Kuhle ukusho ukuthi ifeni yokupholisa i-condenser kanye ne-compressor yeminye imishini yeqhwa ilawulwa yi-contactor efanayo, futhi inkinobho yokucindezela ixhunywe kuchungechunge kumjikelezo oyinhloko we-condenser fan yokupholisa njengokulawula kokumisa kokuqala kwe-condensing fan. Uma ingcindezi yokujiya ingaphezu kuka-1.7MPa, ifeni ejiyayo iqala futhi ime lapho ingaphansi cishe ku-1.4Ma:.

2. Inqubo ye-Deicing

Lapho umtshina wokuqina kweqhwa uhlangana nokugeleza kwamanzi (hhayi iqhwa) imizuzwana embalwa, iphampu yamanzi iyasebenza futhi i-valve ye-solenoid yokudonsa iyavuleka ukuze ikhiphe amanzi kusinki (isikhathi sokudonsa singakhethwa yi-switch time switch on the panel). Ngemuva kokukhipha amanzi ngokwesikhathi esibekiwe, i-valve ye-solenoid yokungena kwamanzi, i-valve ye-solenoid yamanzi kanye nepompo yamanzi ivaliwe, futhi ayisasebenzi phakathi nayo yonke inqubo yokukhipha. Ekuqaleni kokugeleza kwamanzi, kuvulwa i-valve yegesi eshisayo, futhi umhwamuko oshisayo oyisiqandisi ugelezela ku-evaporator ukuze ushise ama-cube eqhwa endaweni ye-evaporator. Amakhiyubhu eqhwa ashelela egumbini lokugcina iqhwa abe yizicucu ngaphansi kwesenzo samandla adonsela phansi, futhi inkinobho yebhokisi iyavulwa, iqede inqubo ye-deicing, bese ingena esimweni sokwenza iqhwa futhi.

0.5T umshini weqhwa we-flake

3. Ukuvala shaqa okuzenzakalelayo lapho iqhwa ligcwele

Lapho inqubo yokuvuna iqhwa isiqediwe futhi isiqandisi sigcwele, ukukhanya kwenkomba yebhokisi lokushintshwa kuyacisha ngalesi sikhathi, futhi umenzi weqhwa uyayeka ukusebenza ngemva kwemizuzwana embalwa.

Isikhathi sokuthumela: Sep-17-2020